Advantages And Application Fields of High-Speed Punching Machine

High-speed punching machine is a kind of mechanical equipment for metal processing, can be 0.1MM to 10MM metal sheet, through a series of uppunching action, complete punching, cutting, bending and other processing processes, to produce the required size and shape of the parts. It has the characteristics of high efficiency, high precision, stability, flexibility and so on, and has become an indispensable important equipment in modern industrial production.

The first is its high efficiency, high-speed punching machine adopts high-speed impact and fast return way for processing, can complete a large number of processing tasks in a short time, thus greatly improving the processing efficiency; Secondly, high precision: the high-speed punching machine adopts a high-speed return method in the processing process, which makes the workpiece have high accuracy and consistency, especially in the mass and high-precision stamping process. In addition, its processing stability: the high-speed punching machine runs smoothly in the processing process, and has a strong degree of automation, which can effectively ensure the stability and quality of processing; At the same time, it has good flexibility: the high-speed punching machine is suitable for various shapes and sizes of the workpiece, in a variety of materials and complex shape processing performance, in addition, the high-speed punching machine can also carry out punching, cooling, forming, unlocking and other operations.

The main uses of the high speed punch are as follows:

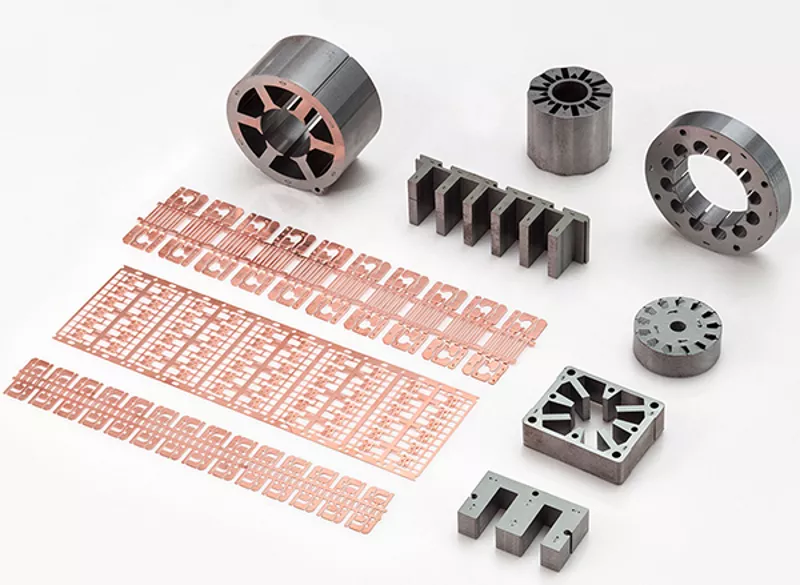

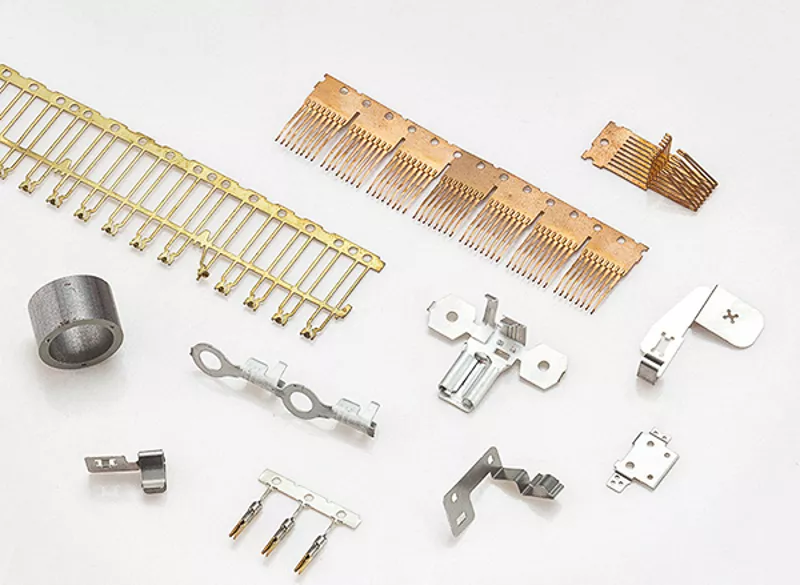

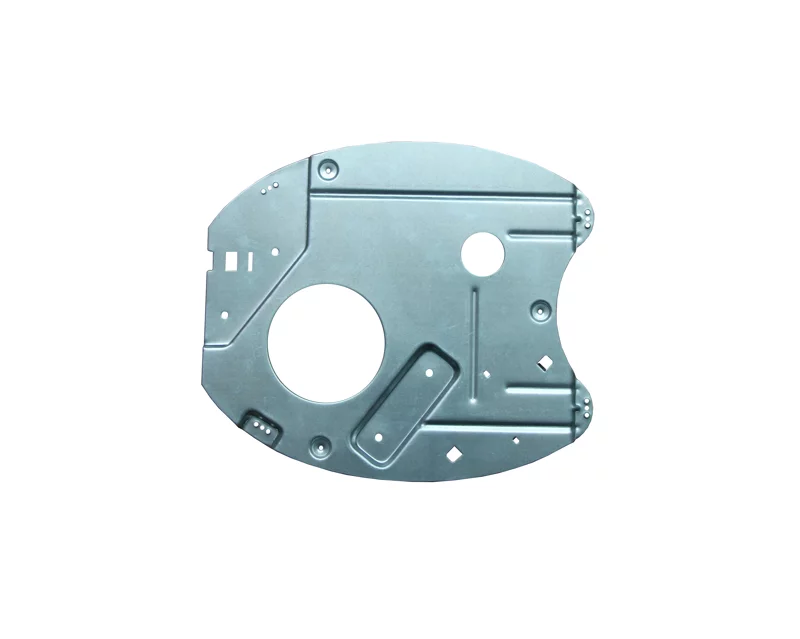

First, the high-speed punching machine can cut the metal sheet into various shapes of parts, such as round, square, rectangular and so on, through the punching process. For example, automobile manufacturing, electronic products, home appliances, machinery and equipment enclosures.

Second, the high-speed punching machine can cut the metal sheet into parts of the required length, which is mainly used for the manufacturing and processing of components, such as various profiles, wire slots, food cans, etc., which can greatly improve production efficiency and reduce production costs.

Third, the high-speed punching machine can bend the metal sheet into the required shape parts through the bending process, which is mainly used to manufacture various curved structures and shells, such as arc, U-shaped, Z-shaped and other shapes of parts, communication equipment, electronic product shells, etc.

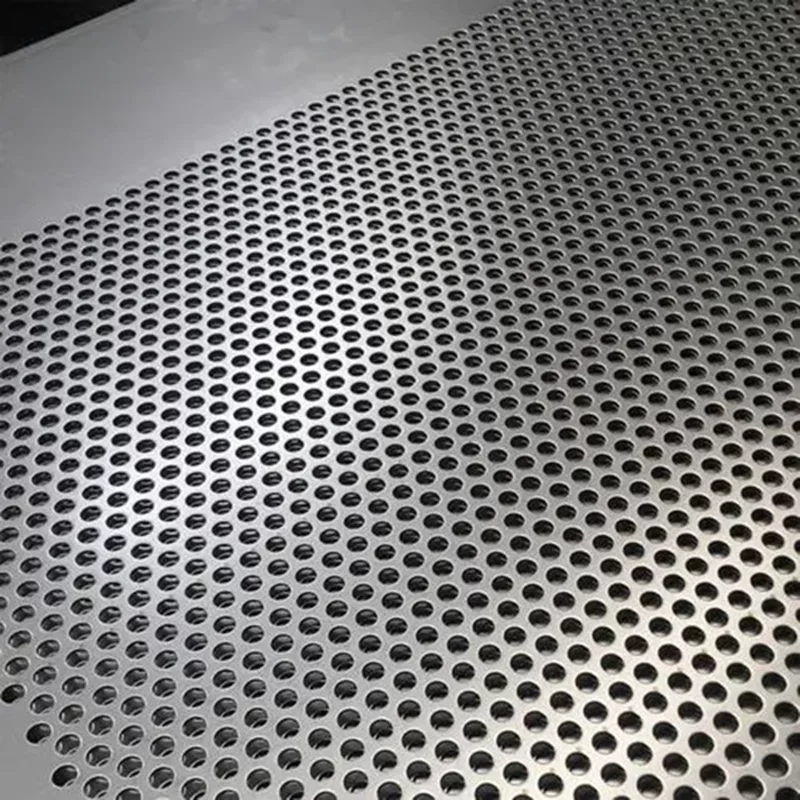

Fourth, the high-speed punching machine can produce round holes, square holes, oval holes and other specifications and shapes of holes on the metal sheet through the punching process, this punching process is mainly used to manufacture various parts and components, such as mechanical equipment transmission holes, connecting holes, ventilation holes, punching mesh boards and so on.

Fifth, the high-speed punching machine can plastic change the metal sheet into the desired shape and size parts through the molding process. The molding process is mainly used to manufacture parts with complex shapes and concave and convex edges, such as aircraft engine parts in the aerospace field, body components in the automotive manufacturing field, etc.

Sixth, the high-speed punching machine can also be combined with other equipment or processes linked operations, such as laser cutting, welding, cold forging, surface treatment, etc., not only can achieve the accuracy and efficiency of processing, but also reduce manual intervention, improve the degree of production automation, reduce labor intensity.

In short, high-speed punching machine as an important equipment for metal processing, its application field is very wide, including automobile, electronics, home appliances, aviation, shipbuilding, construction and other industries. It has the advantages of high efficiency, high precision, stability, flexibility and so on to meet the requirements of different industries for parts and components, is conducive to promoting the development of modern manufacturing industry, has become an indispensable important equipment in modern industrial production.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.