Application of Knuckle Type High Speed Precision on Motor Core

Small electrical appliances motor core high speed punching machine

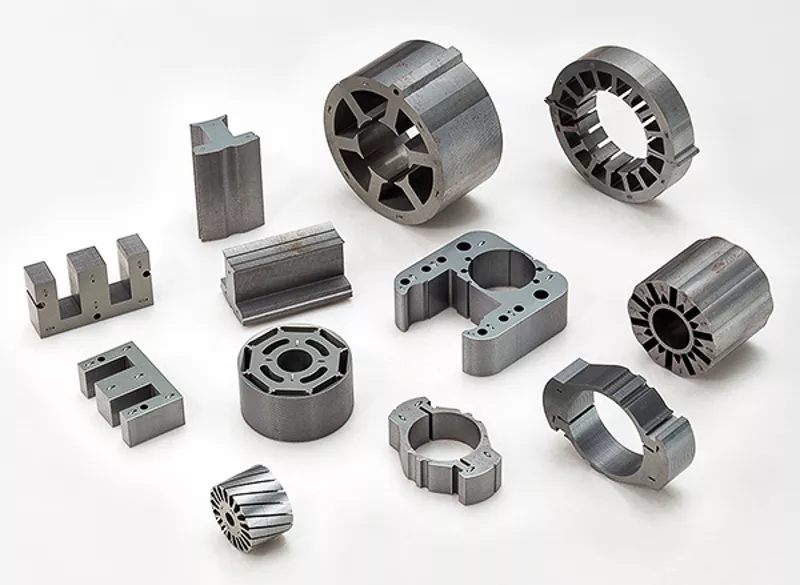

As the core component of the motor, the motor core plays an important role in the whole motor, which is used to increase the magnetic flux of the inductor and achieve the maximum conversion of electromagnetic power. A small electric motor core punch is usually composed of a stator and a rotor. The stator is usually a non-rotating part, and the rotor is usually embedded in the inner position of the stator. A good small home appliance motor core punch requires a precision metal stamping die, the use of automatic riveting process, and then the use of high precision punching machine stamping out. The advantage of doing so is that the plane integrity of its product can be ensured to the greatest extent and the product accuracy can be ensured to the greatest extent.

Utomotive motor core high speed punching machine

Using high-speed progressive giant rotary mold production, each piece can take 90 degrees, 180 degrees and other different Angle rotation mode. The core's flatness, parallelism, verticality, dynamic balance and other indicators are excellent, and the performance is very consistent. Automotive motor core punching machine application range: window motor, seat motor, fan motor, starting motor, EPS power steering motor, etc. According to customer requirements, SPCC, 35W210, 35W440, 50W250, 50W310, 50W470 and other grades of silicon steel materials can be selected, and special performance indicators can also be required.

Motor core high-speed precision automatic punching machine

Usually good quality motor core is the use of this process for professional motor core stamping. High precision metal continuous stamping die with high-speed precision automatic punching motor core, coupled with excellent professional motor core production personnel, in order to maximize the production rate of good motor core.

Motor core automatic high speed punching machine

Modern high-speed stamping precision die can not be separated from the cooperation of high-speed punching machine, the current development trend of modern stamping technology at home and abroad is single-machine automation, mechanization, automatic feeding, automatic unloading, automatic finished products, high-speed stamping technology has been widely developed at home and abroad. The stamping speed of the motor core punching die is generally 200 to 400 times /min, most of which is carried out within the range of medium speed punching. The technical requirement of precision progressive die for high speed precision punching machine is that the sliding block of punching machine has high precision at lower dead point, because it affects the quality of the automatic laminating process of the rotor punching machine in the die to form the core. Now precision stamping equipment is developing in the direction of high speed, high precision and good stability, especially in recent years, precision high-speed punching machine has developed rapidly, which has played a significant role in improving the production efficiency of stamping parts. The automatic high speed punching machine punching motor core is more advanced in design structure, high manufacturing precision, suitable for high-speed stamping of multi-station cemented carbide progressive die, which can greatly improve the service life of progressive die.

Precision of motor core high speed punch

The punching accuracy mainly depends on the geometric accuracy of the punching machine itself and the accuracy of the mold, because the mold gap on the punching parts of the accuracy is very large, the general gap is 0.05 to 0.1 times the thickness of the plate, then the punching 9 mm hole accuracy is about 0.10.

The precision of the motor core punching machine is a precision machine, because the accuracy of a motor core punching machine is the accuracy of each part of the punching machine to the whole, because the fault of any part will multiply the punching machine accuracy. The working principle of the punching machine: The mechanical punching machine is driven by the motor flywheel to accumulate force, the flywheel will be transmitted to the crankshaft, the crankshaft will be the circular motion of the force into the vertical motion of the force, the force to push the slider to do work, thus processing the workpiece.

Safe operating rules for motor core high speed punching machine

1, the speed regulation potentiometer (W) set on the control panel should be adjusted to the lowest point (O point) position before starting.

2, after the main power switch (DK) is turned on, the power indicator is on, and the phase sequence indicator should also be on, otherwise, the phase sequence should be checked whether it is correct.

3. Disconnect the phase after connecting the control loop with the key switch. Three lights should be on at the same time, otherwise it should be checked and troubleshooting.

4, clockwise adjust the "speed regulation" potentiometer, the main motor drives the flywheel to start, the speed should be stable without shock, no impact and other phenomena exist.

5, in the process of connecting the main clutch, the right hand should be operated at the same time. In the formal stamping process, the external control key switch should be connected, and the adjustment key switch is in the reset state, in order to formally work, otherwise the feeding switch and the mold fault signal are out of control.

6, in the formal punching process, because the static difference of the main motor varies with different loads, when punching different parts, the electromagnetic counters set on the control board can be used to correct the speed.

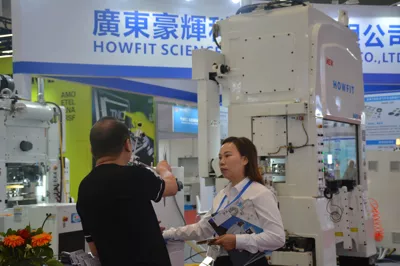

Howfit high speed punching machine

Howfit high speed punching machine is located in Dongguan, China, the geographical position is superior, in Guangzhou, Shenzhen, Hong Kong and other large and medium-sized cities in the center of the development of the axis, the transportation network is extended in all directions. With the continuous development of the motor manufacturing process, modern stamping technology refers to the process method of manufacturing the motor core high-speed punching machine, which is now more and more accepted by the manufacturing motor manufacturers, and the processing means of manufacturing the motor core are becoming more and more advanced. Compared with the original iron core parts with ordinary die and equipment, the modern stamping technology has the characteristics of high automation degree, high dimensional accuracy, long service life of die, etc., which is suitable for mass production of stamping parts. Because the multi-station progressive die is a set of many processing technology on a die punching, reduce the motor manufacturing process, improve the production efficiency of motor manufacturing. Howfit high speed punching machine with a skilled engineer team, improve the strict quality inspection system, to ensure that every stamping equipment is the original quality.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.