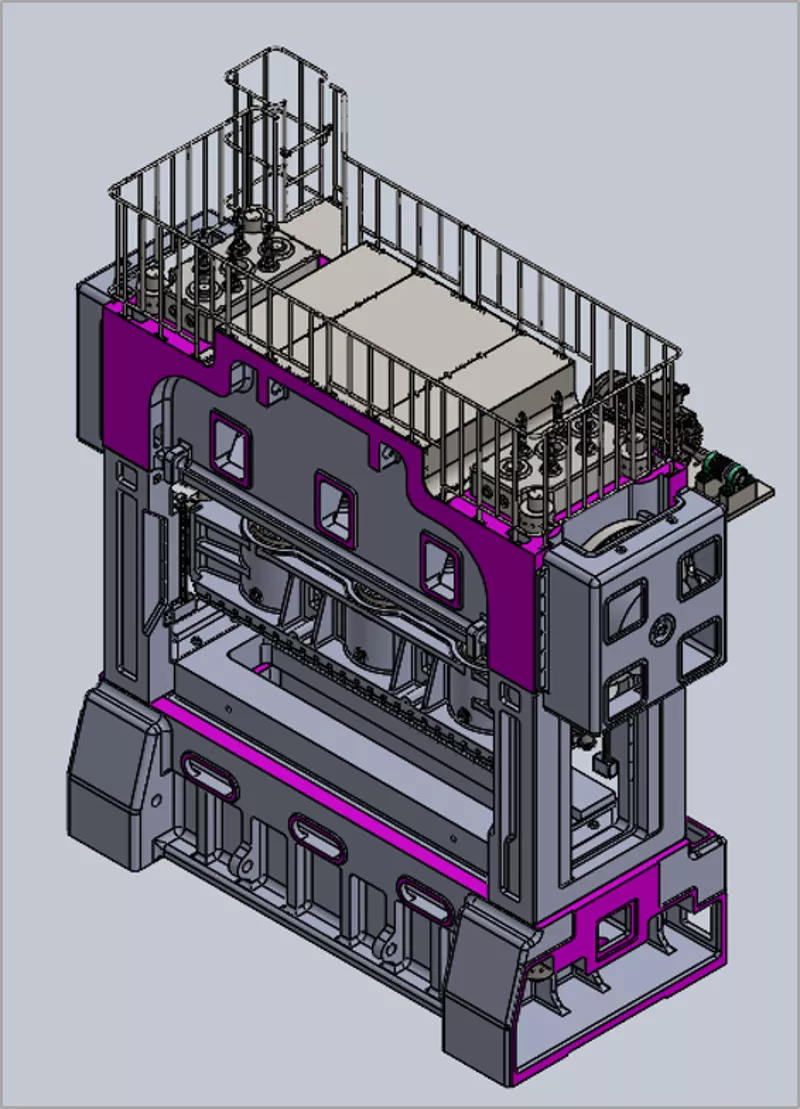

Technical innovation and configuration analysis of HOWFIT DDH 400T ZW-3700 high-speed precision punch press

In today's manufacturing industry, advances in precision punch technology are driving a significant increase in production efficiency and significant improvements in product quality. As a leader in this field, the "DDH 400T ZW-3700" high-speed precision punch stands out among many devices with its excellent technological innovation and high-end configuration, providing users with unprecedented processing capabilities and precision. This article will deeply explore the technical characteristics and configuration advantages of this punch press, revealing its important position in the field of high-end manufacturing.

technological innovation

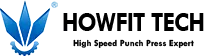

HOWFIT "DDH 400T ZW-3700" high-speed precision punch machine has demonstrated its leading advantages in technological innovation, especially in the application of servo motor mold height adjustment and digital mold height indicator.

HOWFIT

Servo motor mold height adjustment: Using advanced servo motor technology, the mold height can be adjusted quickly and accurately, greatly improving the efficiency and accuracy of mold replacement. This technology allows the punch machine to adapt to the processing needs of materials of different thicknesses, ensuring consistent processing quality and highly customized production capabilities.

Digital mold height indicator: The high-precision digital indicator visually displays mold height data, providing the operator with extremely accurate mold height information and ensuring the accuracy and repeatability of stamping processing. This direct and precise feedback mechanism is one of the key elements for efficient precision machining.

Configuration analysis

In terms of configuration, the "DDH 400T ZW-3700" high-speed precision punch press also performs well, especially configurations such as the hydraulic slide fixing device and the lubricating oil constant temperature cooling + heating device, which provide a solid guarantee for efficient and stable production.

Hydraulic slider fixing device: This configuration improves the stability of the slider during high-speed movement and reduces possible accuracy losses due to vibration. When processing large loads or high-speed stamping, it ensures processing accuracy and long-term stable operation of the equipment.

Lubricating oil constant temperature cooling + heating device: Keeping the lubricating oil temperature constant is the key to ensuring the normal operation of mechanical components. The equipment can automatically adjust the lubricating oil temperature according to the ambient temperature, whether it is heating in a cold environment or cooling in a hot environment, ensuring the best performance of the equipment and extending its service life.

It can be seen from the above technological innovation and configuration analysis that the design and manufacturing of the "DDH 400T ZW-3700" high-speed precision punch fully reflects the deep understanding of the needs of the precision machining field and the application of advanced technology. It not only provides excellent processing accuracy and efficiency, but also ensures ease of operation and long-term stability of the equipment, becoming one of the indispensable key equipment in the high-end manufacturing field.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.