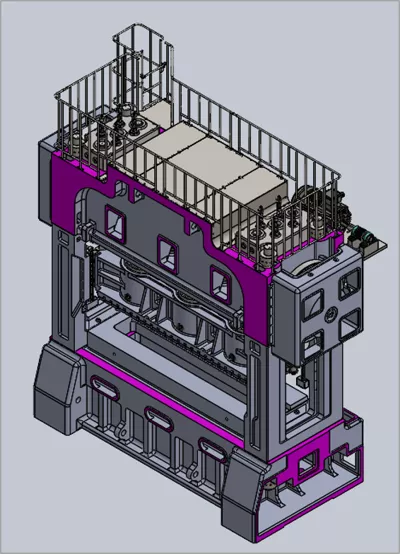

Manufacturing process analysis of HOWFIT DDH 400T ZW-3700

HOWFIT DDH 400T ZW-3700

high-speed precision punch machine is an important equipment in the manufacturing industry and has excellent performance in the field of stamping processing. This article will deeply explore the manufacturing process of this punch press, analyze its key role in machine performance and quality, detail the impact of key processes on the rigidity and vibration performance of the fuselage, and explore innovative elements in the design to ensure the operational stability of the machine. At the same time, the applied lubrication and balancing devices are analyzed to ensure that the punch press operates efficiently for a long time.

The critical role of manufacturing processes

The manufacturing process of the punch press is directly related to the machine performance and quality. The manufacturing process of "DDH 400T ZW-3700" focuses on fine control of every link to ensure that the machine can maintain high precision and stability during high-speed stamping.

Three-section combined structure and alloy casting stress relief treatment

"DDH 400T ZW-3700" adopts a three-stage combined structure, which is tightened by twice the nominal force and has excellent overall rigidity. The deflection value is strictly controlled below 1/18000, which provides a solid foundation for the stable operation of the machine. The fuselage is made of high-quality alloy castings and has been stress-relieved to provide excellent vibration damping performance to ensure long-term and high-precision operation. The application of these processes enables the punch press to maintain the stability of the machine body during high-speed operation, reducing vibration and noise, and improving the reliability of the machine.

Finite element analysis of critical castings

After finite element analysis, the key castings have reasonable stress and small deformation. This means that critical components can withstand reasonable forces without excessive deformation during press operation. This helps maintain the machine's high accuracy and long-term stability.

Prestressed eight-sided circulating needle roller guide and reverse symmetrical dynamic balancing device of the slide block

The slider adopts prestressed eight-sided circulating needle roller guide. This design ensures the verticality and parallelism of the slider's up and down movement. Needle roller bearings have large load capacity, high precision, simple maintenance, and long life, which makes the mold production cycle longer and more durable. In addition, the punch press adopts an inverse symmetrical dynamic balancing device to balance the horizontal and vertical inertial forces generated during operation to ensure smooth operation of the entire machine. These two innovative designs improve the stability and operating efficiency of the punch press.

Applications of Lubricating and Balancing Devices

"DDH 400T ZW-3700" also uses a large-volume thin oil lubrication device to take away the heat generated during operation in a timely manner, thereby ensuring stable bottom dead center accuracy of the entire machine. The airbag static balancing device not only makes the machine run reliably and smoothly, but also protects the transmission components from wear during mold height adjustment, thereby ensuring the durability of the mold adjustment mechanism. The application of these devices extends the service life of the punch press and reduces maintenance costs.

Fine control of processing technology

The processing technology of "DDH 400T ZW-3700" is also one of its advantages. After the casting is completed, it undergoes multiple annealing treatments, including vibration aging treatment, to eliminate internal stress and improve machining accuracy. Finally, laser trackers are used for inspection to ensure that the quality of the product reaches the highest standards.

in conclusion

DDH 400T ZW-3700" high-speed precision punch press adopts advanced manufacturing technology, including three-stage combined structure, stress relief treatment of alloy castings, and prestressed eight-sided cyclic rolling of the slider.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.