High performance and application examples of HOWFIT DDH 400T ZW-3700

In modern manufacturing, high-speed precision punching machines have become indispensable equipment due to their excellent performance and reliability.HOWFIT DDH 400T ZW-3700 punch press provides effective solutions for various complex and high-precision metal processing with its advanced technology and excellent design concept. This article will provide an in-depth analysis of the key performance indicators of DDH 400T ZW-3700 and its performance under different working conditions.

1. Specifications and importance of punch press

The DDH 400T ZW-3700 punch press is designed with various key performance indicators in mind to meet high-precision and high-speed requirements. The main specifications include a nominal force of 4000KN, a motor power of 90kw and a workbench area of 3700x1200mm. These parameters not only determine the basic performance of the machine, but also affect processing accuracy and production efficiency.

2. Nominal force: 4000KN

Nominal force is the core of punch press performance. The force of 4000KN allows the DDH 400T ZW-3700 to handle a variety of materials, from light and thin metal sheets to thick and heavy metal plates. This powerful force ensures precision and consistency in material processing under different working conditions, especially when operating at high speeds.

3. Motor power: 90kw

The motor is the power source of the punch press. The 90kw high-efficiency motor ensures the reliability and stability of the DDH 400T ZW-3700 in high-speed operation. The high-power motor not only provides strong power, but also ensures stability and low failure rate in long-term operation.

4. Workbench area: 3700x1200mm

The spacious workbench area provides enough space for processing large workpieces. The size of 3700x1200mm allows multiple small workpieces or one large workpiece to be placed simultaneously, enhancing the machine's applicability and flexibility. This is of great significance for improving production efficiency and reducing mold change time.

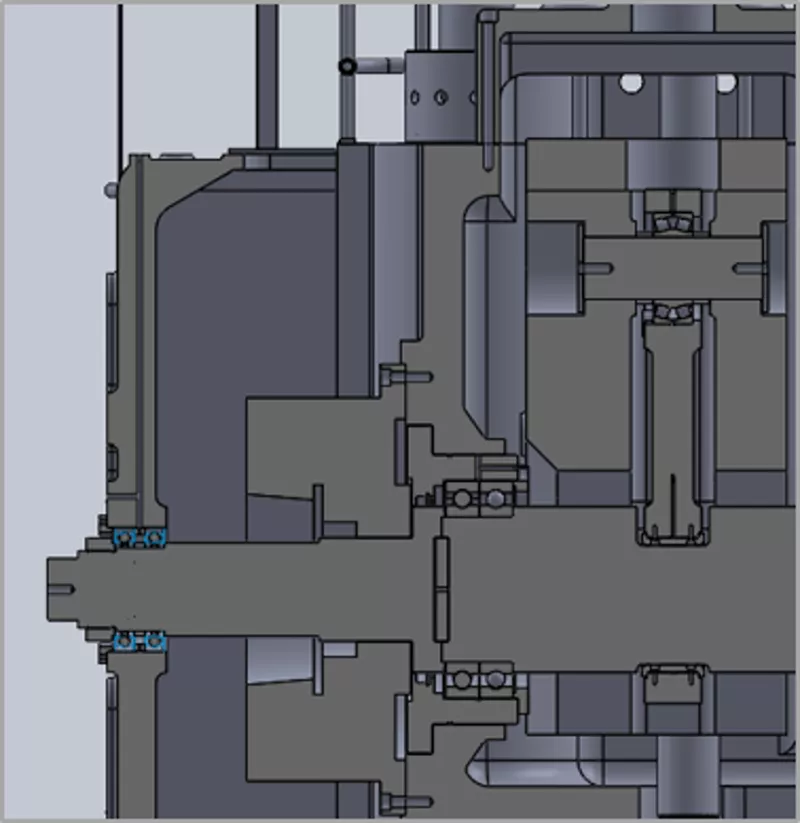

5. Advanced configuration and features of the device

DDH 400T ZW-3700 is equipped with many advanced functions, such as servo motor mold height adjustment, inching positioning function, digital mold height indicator, hydraulic slider fixing device, etc. These configurations improve the machine's operational convenience and safety while ensuring high precision and efficiency in the processing process.

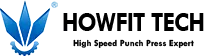

6. Optimization of structure and process

The three-section combined structure of the fuselage and the use of high-quality alloy castings ensure the rigidity and vibration-absorbing performance of the entire machine. Finite element analysis of key castings and multiple heat treatment processes further improve the stability and durability of the machine. These design optimizations enable the DDH 400T ZW-3700 to maintain high accuracy during long-term operation and extend the service life of the machine.

in conclusion

DDH 400T ZW-3700 punch press occupies an important position in the field of high-speed precision stamping with its advanced design and excellent performance. Its high-performance configuration, optimized structural design and refined process management jointly ensure its excellent performance under various working conditions.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.