Trends in Intelligent Manufacturing and Sustainable Development of High-Speed Punching

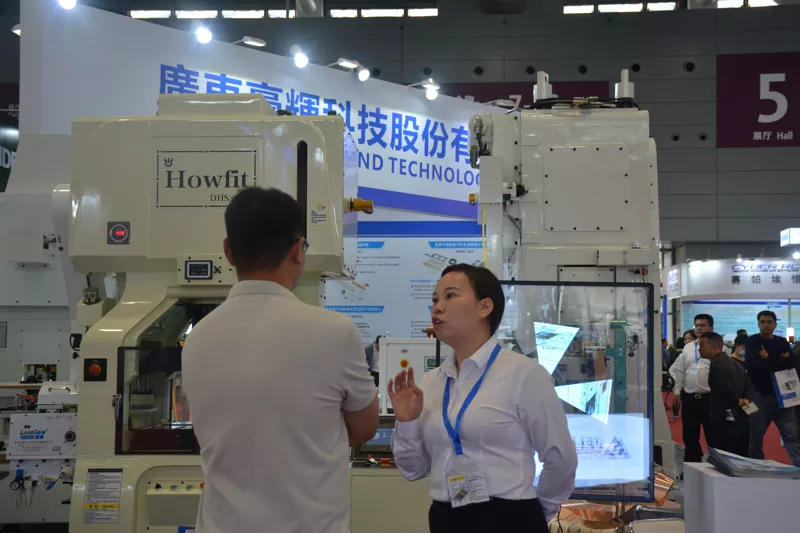

With the continuous evolution of technology and shifts in market demands, the high-speed punching industry is witnessing a series of noteworthy future trends. These trends not only shape the landscape of manufacturing but also drive high-speed punching manufacturers to adapt to the challenges and opportunities of the global market.

### 1. Leading the Wave of Smart Manufacturing

In the future, the high-speed punching manufacturing industry will enter a new era of smart manufacturing. The integration of industrial Internet, digital manufacturing technology, and artificial intelligence will propel the automation levels of factories. Intelligent machines and advanced data analytics systems will become valuable assistants on production lines, resulting in higher production efficiency and more precise quality control. The widespread application of industrial robots and automation systems will make the production process more flexible and adjustable to rapidly changing market demands.

### 2. Extensive Application of New Materials and Composite Materials

As new materials and composite materials become more prevalent in the manufacturing industry, the high-speed punching industry will continually face the demand for processing capabilities across various materials. Manufacturers will need to adapt to this trend by introducing more advanced equipment and processing technologies to meet the flexible processing needs of multiple materials. This may drive innovation, encouraging manufacturers to seek more efficient processing methods to ensure efficient and accurate production.

### 3. Customized Production Becomes Mainstream

In the future, the growing demand for personalized and customized products will directly impact the high-speed punching manufacturing industry. Manufacturers will focus more on providing flexible production solutions to meet specific customer requirements. Customized production necessitates more flexible production lines and intelligent manufacturing systems to quickly adjust production processes and meet continually changing market demands.

### 4. Rise of Sustainable Manufacturing

As the importance of environmental sustainability continues to grow, the high-speed punching industry will strengthen its focus on energy efficiency, emissions reduction, and waste management. Manufacturers will adopt more environmentally friendly production technologies to minimize waste generation, while also focusing on energy efficiency and green manufacturing practices. Sustainable manufacturing will become a key factor for long-term competitiveness in the industry.

### 5. International Collaboration and Supply Chain Optimization

The trend of globalization will continue to drive the high-speed punching industry to seek international partnerships. To optimize supply chains, reduce production costs, and enhance product competitiveness, manufacturers will actively pursue cross-border collaborations. This international collaboration will bring opportunities for shared innovation and resources, propelling the collective progress of the global high-speed punching industry.

In this era filled with challenges and opportunities, the high-speed punching industry is striving to shape its future through technological innovation, sustainable manufacturing, and international collaboration. Only by closely following these trends and continuously adapting to market changes can manufacturers stand out in fierce competition and achieve sustainable success.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.