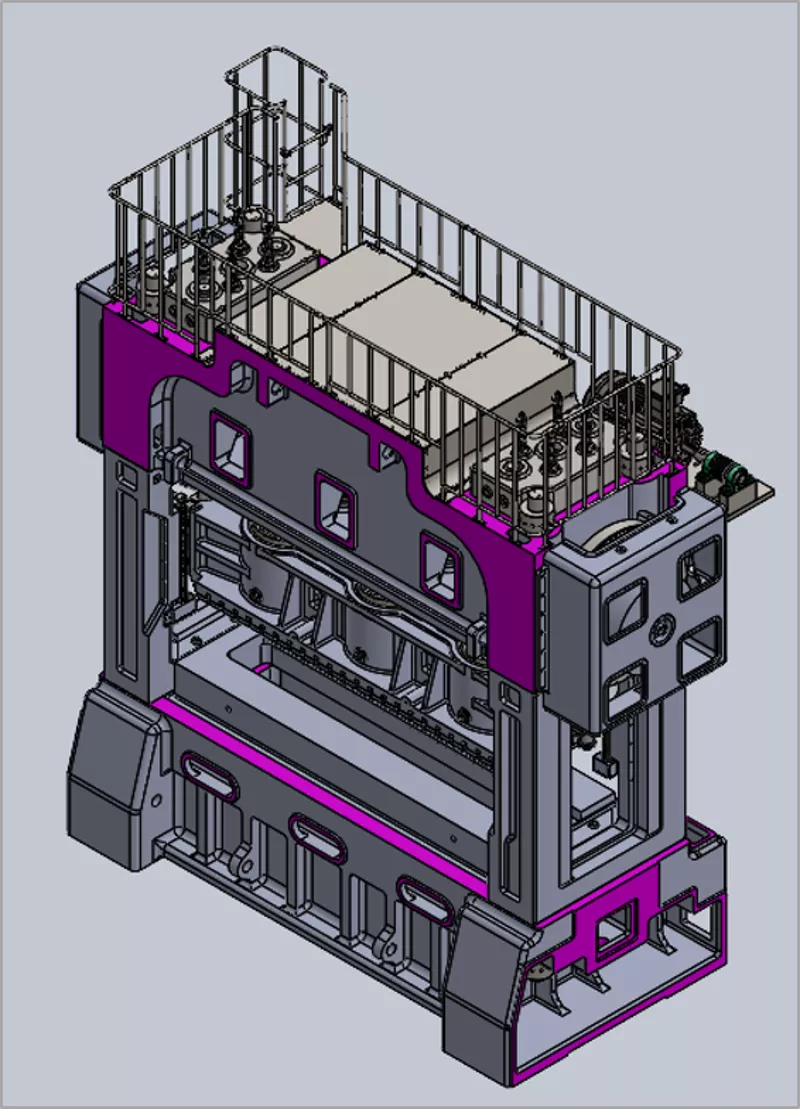

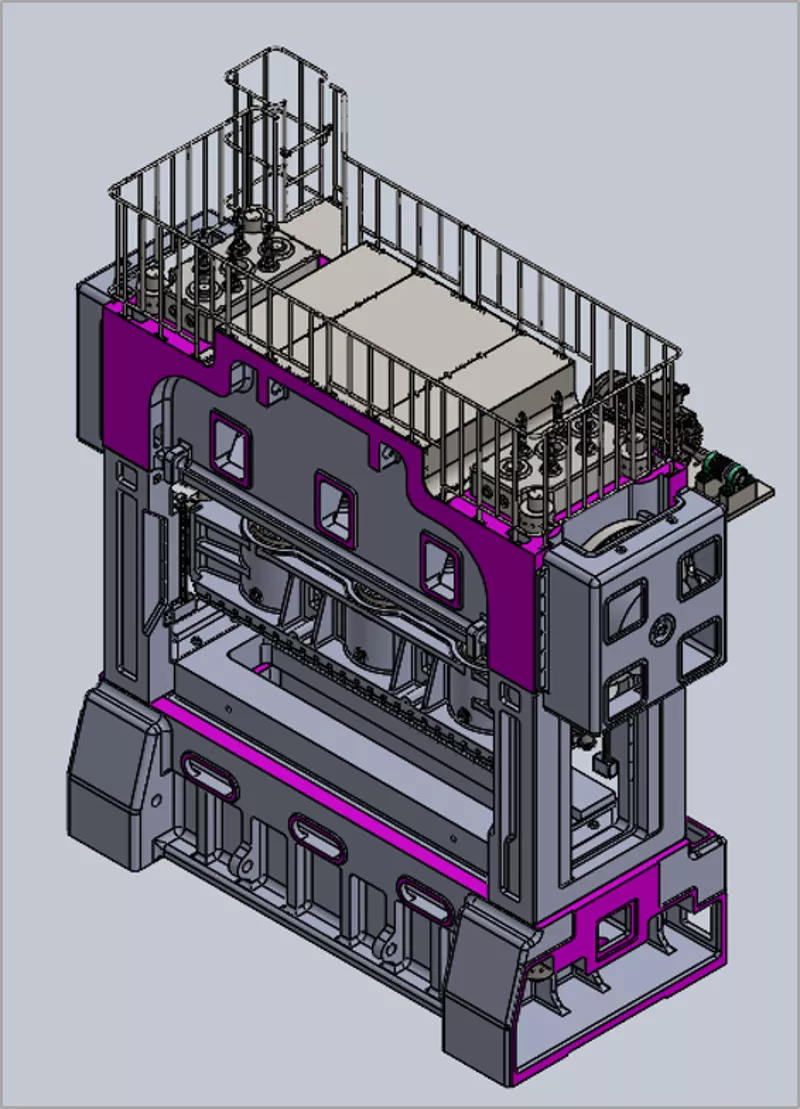

Precision craftsmanship and quality assurance of HOWFIT DDH 400T ZW-3700

The manufacturing process of a press plays a crucial role in determining its performance and quality. This article delves into the manufacturing craftsmanship of the DDH 400T ZW-3700 high-speed precision press, focusing on body construction, slider design, and lubrication system to unveil its foundation for efficient and stable operation.

**Body Manufacturing:**

The DDH 400T ZW-3700 adopts a three-stage composite structure, tightened with twice the nominal force to ensure overall rigidity, with the deflection value strictly controlled at 1/18000 for superior stability. The body is constructed with high-quality alloy castings that undergo stress-relieving treatments, exhibiting excellent vibration damping performance to ensure long-term precision. Key components undergo finite element analysis for reasonable force distribution and minimal deformation, enhancing the machine's reliability and stability.

**Slider Design:**

The slider features a pre-stressed eight-face cyclical needle guide, complemented by a reverse symmetrical dynamic balancing system that effectively balances horizontal and vertical inertial forces during operation, ensuring smoother overall machine performance. The use of high-speed heavy-duty sliding bearings in connecting rods and six-point ultra-close support areas guarantees stability during stamping processes. This design enhances slider precision and longevity, contributing to prolonged mold life and durability.

**Lubrication System:**

To guarantee prolonged and efficient operation, the DDH 400T ZW-3700 employs a large-volume thin oil lubrication system and an airbag-type static balance system. The large-volume thin oil lubrication system efficiently dissipates heat generated during operation, maintaining stable precision at the bottom dead center. The airbag-type static balance system ensures reliable and stable operation, protecting transmission components from wear during mold height adjustments, ensuring the durability of the tooling mechanism.

**DDH 400T ZW-3700 Equipment Configuration and Parameters:**

1. Servo motor mold height adjustment

2. Inching positioning function

3. Digital mold height indicator

4. Two sets of misfeed detection

5. Single action with 0°, 90°, 180°, 270° positioning function

6. Main unit forward and reverse device

7. Hydraulic slider fixing device

8. Lubricating oil constant temperature cooling + heating device

9. Separated brake clutch

10. Independent electrical control box + mobile operating platform

11. Work light

12. Maintenance tools and toolbox

13. Eight-group batch control

14. Lubrication circulation pump station

15. Safety grating (front and rear, 2 sets)

16. Front and rear safety door device

**Specifications:**

- Nominal force: 4000KN

- Capability focal point: 3.0mm

- Stroke: 30mm

- Strokes per minute: 80-250s.p.m

- Closing height: 500-560mm

- Worktable area: 3700x1200mm

- Slider area: 3700x1000mm

- Adjustment amount: 60mm

- Material drop hole: 3300x440mm

- Motor: 90kw

- Upper mold bearing weight: 3.5 tons

- Feeding line height: 300±50mm

- Machine dimensions: 5960*2760*5710mm

**DDH 400T ZW-3700 Headstock Processing Technique:**

1. After casting is complete, undergo the first annealing.

2. Rough machining, followed by the second annealing.

3. Vibration aging treatment with manual interference achieves up to 98% elimination of internal stresses.

4. Precision machining follows.

5. Upon completion, use a laser tracker (American API) for inspection.

Through this in-depth exploration of the precision craftsmanship and quality assurance of the DDH 400T ZW-3700 high-speed precision press, it becomes apparent that its advanced manufacturing processes and innovative designs provide users with high-performance, efficient, and stable press equipment, delivering greater convenience and benefits to industrial production.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.