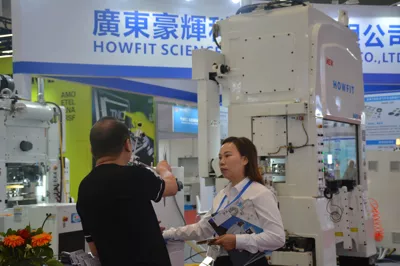

HOWFIT gantry 400-ton high speed punch press A model of precision manufacturing

In today's manufacturing industry, high-speed punch machines have become important tools in the field of precision machining due to their excellent performance and high-efficiency production capabilities. The gantry 400-ton high-speed punch press launched by HOWFIT Gaojiang Precision Machinery has once again proved Haohui's leadership in the field of high-speed precision stamping technology with its advanced technology and powerful functions.

## product description

HOWFIT gantry 400-ton high-speed punch press model DDH-400T-ZW-3700 is a stamping equipment specially designed for high-precision and mass production. The equipment adopts JIS special-grade precision standards to ensure extremely high processing accuracy and stable performance. It can operate at a speed of up to 300 times/minute, is equipped with a nominal force of 4000KN, and has a capacity generation point of 3.0mm, which perfectly meets the needs of various difficult and mass production.

## Technical parameters and equipment configuration

### Core parameters

- **Model and brand**: DDH-400T-ZW-3700, Haohui Gaojiang Precision Machinery

- **Accuracy**: JIS special grade, ensuring excellent processing quality

- **Speed and Tonnage**: Highly efficient production capacity, 400 tons tonnage, 300 times/min speed

- **Number of strokes and closing height**: Flexible adjustment, 80-250s.p.m stroke number, 500-560mm closing height

- **Work surface and slider area**: Extensive 3700x1200mm work surface, 3700x1000mm slider area

### configuration list

- **Servo motor mold height adjustment** and **inch positioning function**: precise control to improve operational flexibility

- **Digital mold height indicator**: intuitive display for easy operation

- **Two sets of misfeed detection** and **Single action have multi-angle positioning function**: improve safety and processing accuracy

- **Main engine forward and reverse device** and **Hydraulic slider fixing device**: optimize operation and enhance stability

- **Lubricating oil constant temperature cooling + heating device**: ensures long-term and efficient operation of the machinery

- **Safety grating** and **Front and rear safety door devices**: ensure operator safety

### Additional equipment

- **Double-head material rack, S-type leveler, dual servo feeder**: complete pre-processing equipment to ensure the smooth supply of material strips

- **Mold lifter, mold moving arm + support base**: Convenient and fast mold replacement to improve production efficiency

- **Spring damping anti-vibration foot pads**: Effectively reduce vibration when the equipment is running and extend the service life of the equipment

- **Scissor solenoid valve, thermostatic oil cooler**: high-quality accessories to ensure stable operation of the equipment

## Conclusion

HOWFIT gantry 400-ton high-speed punch press DDH-400T-ZW-3700 is an ideal choice for efficient and precision manufacturing. With its powerful performance parameters, user-friendly design and high configuration flexibility, it can meet a wide range of production needs and provides an efficient and reliable solution for the manufacturing industry. Whether in terms of production efficiency, ease of operation or product quality, HOWFIT's high-speed punch press is the leader in the market and brings real value to customers.

After an in-depth discussion of the core parameters and configuration of the HOWFIT gantry 400-ton high-speed punch press DDH-400T-ZW-3700, it is worth emphasizing its main features. These features not only highlight the pursuit of technological innovation by Haohui Gaojiang Precision Machinery, It also directly affects the operating efficiency, product quality and maintenance costs of the equipment. Here is a further analysis of these characteristics:

### 1. Extra wide workbench

It has a workbench area with a maximum width of 3700mm, which allows the equipment to easily cope with more complex and diverse processing technology requirements. The extra-wide workbench not only provides the possibility for processing large materials, but also greatly improves flexibility and production efficiency.

### 2. Stable bottom dead center repeatability

Stable bottom dead center repeatability not only reduces mold wear and ensures product accuracy, but also effectively reduces bottom dead center runout. This not only extends the service life of the mold, but also ensures the consistency of product quality during long-term production processes, providing a reliable guarantee for processing with high-precision requirements.

### 3. Minimize thermal displacement

The thermal control technology mastered in the field of small high-speed punch presses is used to suppress thermal displacement during equipment operation to the greatest extent, thus improving the accuracy of product processing. The application of this technology is a reflection of HOWFIT's continuous technological innovation and refined management concepts, ensuring stable machine performance and accurate product dimensions under continuous high-speed operating conditions.

### 4. High-precision 8-sided slider guide

This equipment adopts 8-sided needle roller slider guide rail, which not only has ultra-high load-bearing capacity, but also the long guide rail design makes it better able to withstand eccentric loads. This design not only ensures high-precision operation of the equipment, but also makes subsequent maintenance more convenient, reduces maintenance costs, and increases the service life of the equipment.

Based on these characteristics, HOWFIT gantry 400-ton high-speed punch press DDH-400T-ZW-3700 is undoubtedly an excellent equipment on the market with high performance, high precision and easy maintenance. Through innovative design and exquisite craftsmanship, it meets the dual needs of high efficiency and high-quality production, and provides powerful production solutions for the majority of manufacturing companies.

With years of hands-on experience, I have honed my skills in navigating the complexities of global commerce, offering invaluable insights and solutions to address customer needs. My commitment to excellence and dedication to customer satisfaction ensure that I deliver exceptional service, guiding clients through every step of the trading process with confidence and proficiency.