As manufacturing continues to evolve, so does punch technology. Here are some key trends for the future of punch press technology:

Digitization and automation

With the development of Industry 4.0,

technology is developing rapidly in the direction of digitalization and automation. Digital technology allows punch presses to be integrated with other manufacturing equipment for real-time data transmission and monitoring. Automated systems can achieve higher production efficiency and reduce manual intervention while improving production repeatability and consistency.

Intelligent control and monitoring

Future punch presses will be equipped with more intelligent control systems that can automatically adjust parameters to respond to the needs of different workpieces. These systems will use machine learning and artificial intelligence to improve punch press performance and be able to predict and prevent potential failures. The intelligent monitoring system will track the performance of the punch press in real time to ensure the stability of production.

Environmental protection and sustainability

The manufacturing industry is constantly looking for ways to reduce its environmental impact, so the future of punch press technology will also focus on environmental protection and sustainability. Punch press manufacturers will adopt more energy-efficient designs and production processes while reducing waste and wasted resources. Sustainable materials and production methods will become more widely used in punch press manufacturing.

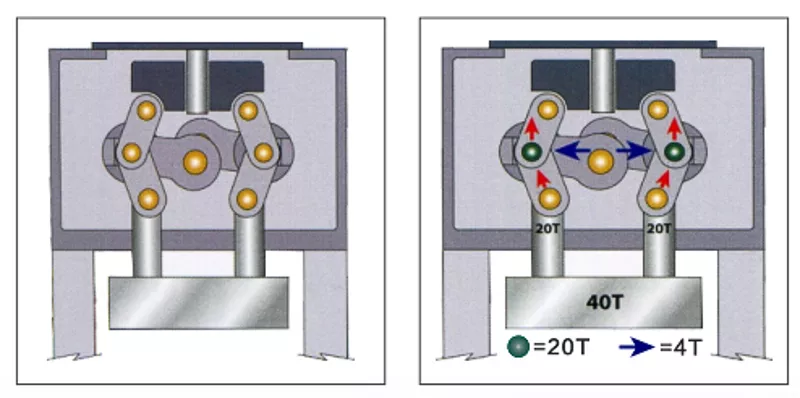

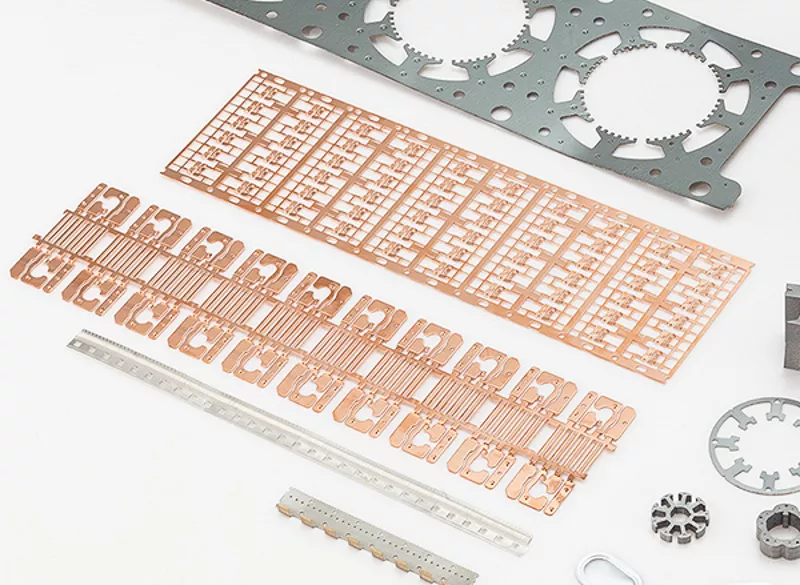

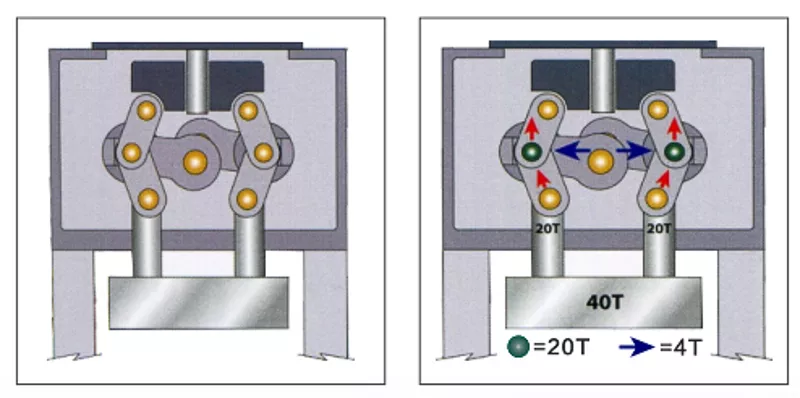

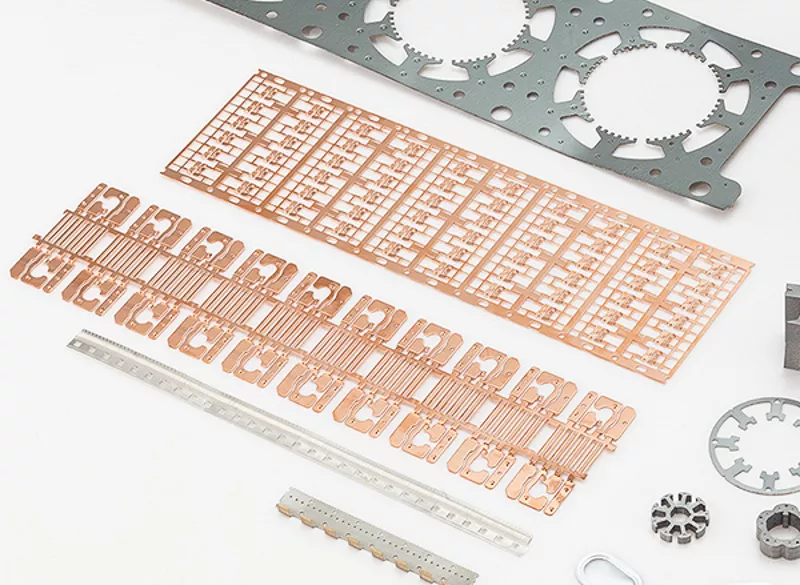

Stamping applications of new materials and new processes

As new materials and new processes emerge, punch technology will also adapt to these changes. Punch presses need to accommodate more challenging materials such as high-strength steel and composites. New processes, such as laser stamping and magnetic stamping, will bring more innovation and benefits to the manufacturing industry.

Conclusion and outlook

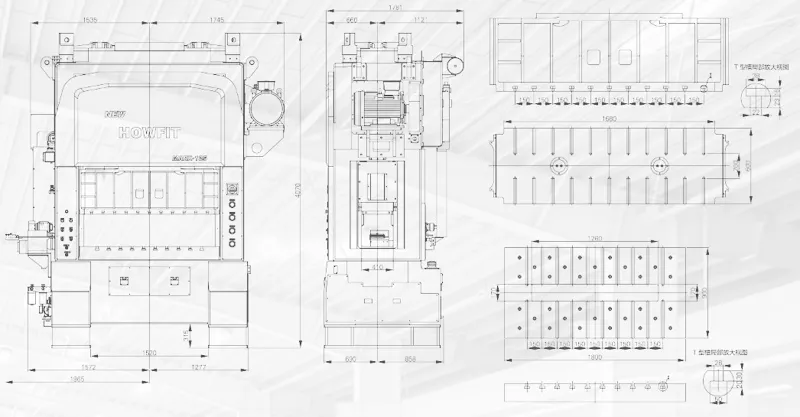

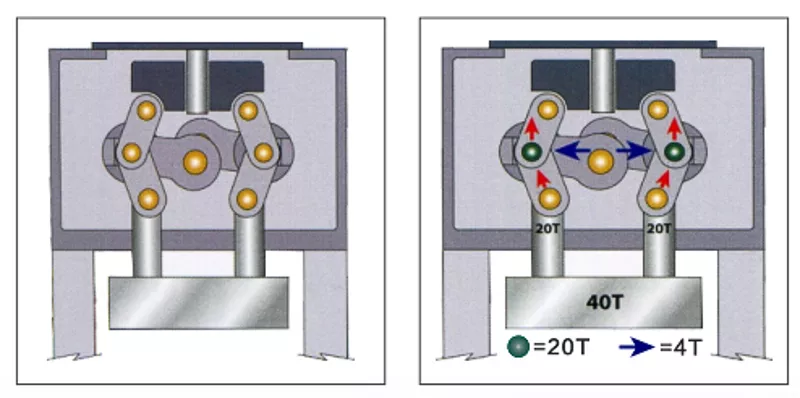

The knuckle-type high-speed precision punch is an indispensable part of modern manufacturing. It provides key manufacturing solutions for various industries with its characteristics of high speed, high precision and high efficiency. From an engineering and technical point of view, the design and working principle of the punch press are related to product quality, production efficiency and environmental sustainability.

As punch press technology continues to evolve, we can expect more innovations and improvements. Digitalization, automation, intelligent control and monitoring systems will improve the performance of punch presses, while greener designs and new materials will make manufacturing more sustainable.

Most importantly, engineering technology plays a key role in the development of punch press technology. The unremitting efforts of engineers and researchers will promote the continuous advancement of punch technology and bring more opportunities and challenges to the manufacturing industry.

In the future, we can expect to see knuckle-type high-speed precision punches playing a more important role in the manufacturing industry, providing more innovations and solutions to various industries. The application of these technologies will promote the continuous development of manufacturing industry, making it more efficient, environmentally friendly and competitive.

Hopefully, this article has provided readers with a comprehensive understanding of knuckle-type high-speed precision punches and the importance of engineering technology in manufacturing. The future of punch press technology is promising, and we look forward to seeing its continued development and innovation.