HC-85T C Type Three Guide Column High Speed Precision Press

Basic Attributes

- Press Capacity 850 kN

- Stroke Length 30x40x50 mm

- Max. S.P.M. 600x550x500 S.P.M.

- Min. S.P.M. 200 S.P.M.

- Die Height 315-365x310-360x305-355 mm

- Die Height Adjustment 50 mm

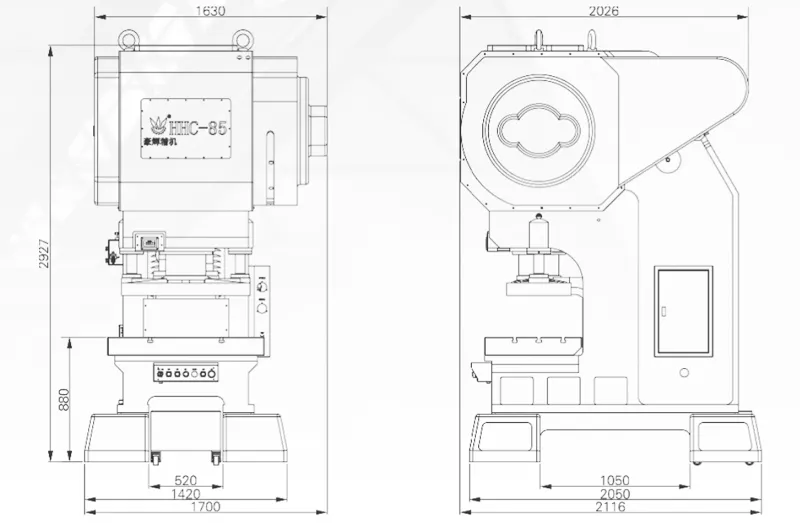

- Slide Area 900x450 mm

- Bolster Area 1100x680x130 mm

- Bolster Opening 150x820 mm

- Main Motor Power 18.5x4 kW×P

- Machine Weight 14 ton

- Model HC-85T

Main Features of HC-85T Precision Press Machine

- The bed is made of high strength cast iron with internal stress relief, which makes the material stable and accuracy unchanged and most suitable for continuous stamping production.

- The fixed guide pillars on both sides of the slider are added to the traditional slider structure to make the slider have better resistance to deflection load and reduce the wear on one side, which is suitable for the use of large dies in long processes.

- The die adjustment is equipped with die height display and hydraulic locking device, which is convenient for die adjustment operation.

- Human-machine interface microcomputer control, value, fault monitoring system screen display for easy operation.

- Adopt die height adjustment motor, with die height indicator, easy to adjust the die height.

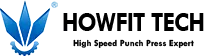

Dimension of the HC-85T Precision Press Machine

Main Specifications of HC-85T Precision Press Machine

[@@Specification]

Finished Products Produced By HC-85T Precision Press Machine

Advantages of HC-85T Precision Press Machine

High speed press for EI lamination is suitable for EI sheet stamping. EI precision punch is a powerful toolfor mass production of EI. As long as the manufacturer matches a set of dies first, it can stamp outcontinuously on the precision punch. It has the advantages of high speed, high precision, economical benefitand wide utilization.

High speed press for EI lamination can be equipped with automatic feeders of different grades andspecifications for automatic production. Through a reasonable product mix, it is convenient to realize theproduction mode of one person managing multiple machines.

The machine structure consists of high rigidity casting iron, which guarantee the stability, the accuracy andthe long-term usage. With the forced lubrication, the thermal deformation would be minimized. The doublepillar and one plunger guide was made of brass and it reduced the friction to the minimum. Balance weightfor optional to reduce vibration. HMI is controlled by microcomputer. With the advanced computer controller,Howfit Presses are using unique design stamping operation software. The computer has strong function andlarge memory capacity. With the guidance parameter setting, it has the function of fault revelation andmakes the mechanical operation simpler.

Optional Configurations of HC-85T Precision Press Machine

- Roller Feeder (Width Selection: 105/138 mm)

- Gripper Feeder (Single/Double)

- Gear Feeder (Width Selection: 150/200/300/400)

- Electric Plate (500kg Bearable)

- Double Heads Material Receiver

- Bottom dead center monitors Single Point

- Bottom dead center monitors Double Point

- Electric Die Height Adjustment Function

- Work Light